Liquid Penetrant Testing: Fundamentals and NDT Personnel Training

- Thomas R. Hay, Ph.D., P.E

- Feb 28, 2022

- 4 min read

Updated: Dec 2, 2025

Liquid Penetrant Testing (LPT) is a non-destructive testing (NDT) technique used to detect surface flaws that may not be detectable to the naked eye under standard lighting conditions. Liquid penetrant testing is typically used for non-magnetic metals to reveal surface flaws and in some cases plastics. Penetrant testing is one of the simplest and most economical non-destructive testing techniques. Additionally, it requires the least investment in personnel in terms of formal technical training and on-the-job hours. This article discusses some of the basic principles of penetrant testing and how to qualify NDT personnel to perform NDT in this method. TKS training courses are eligible for Workforce and Economic Development Network of Pennsylvania (WEDnetPA) funding for Pennsylvania based students and employers.

Figure 1: Penetrant Testing – Affordable Non-destructive Testing.

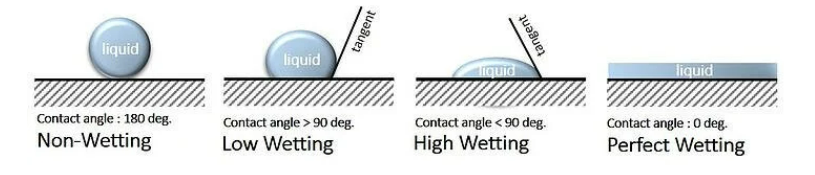

There are couple technical principles associated with liquid penetrant testing that drive the quality control process: Surface Wetting and Capillary Action. PT is most effective when the penetrant uniformly wets the surface of the part tested. Surface tension exists between the liquid penetrant molecules and the inspection surface due to cohesive forces. When a liquid penetrant interacts with a specimen’s surface, a cohesive force responsible for surface tension competes with an adhesive force between the molecules of the liquid and the solid surface. This causes the surface to be wet, or to have a good wetting ability. This results in a contact angle between the penetrant and the surface of the test surface. If the angle is equal to or greater than a 90-degree angle, the wetting is considered to be poor.

Figure 1 Penetrant testing and surface wetting based off contact angle.

As the penetrant dwells on the surface of the specimen, it slowly migrates into cavities of interest that are open at the surface of the test piece. This method depends on a few critical factors that allow it to function correctly and yield results. The ability of the liquid to wet the entire surface, cleanliness of the flaw, and other variables contribute to success or failure of the NDT method.

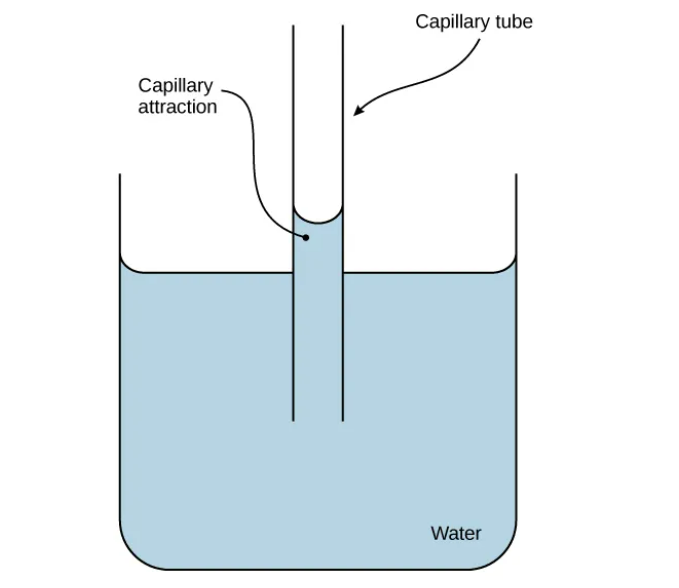

Capillary action is the second physical mechanism that drives excellent testing results. Capillary action drives dye penetration into the depth of a surface crack and draws the penetrant from the crack depth to be contrasted against the developed.

Figure 2: Penetrant testing – capillary action.

The liquid penetrant that enters the flaw must emerge from the flaw after the cleaning process to be viewed against the contrasting developer. Once developer is applied, it creates capillary paths. The penetrant meets the powder, and competes with the freshly cleaned surface of the piece for the penetrant to flow from the defect. This penetrant will slowly create an equilibrium force with the developer until the penetrant has emerged from the crack.

The primary penetrant testing methods are water-washable penetrant, post-emulsifiable penetrants, and solvent-removable penetrants. The exact penetrant testing procedure differs by method. The steps outlined below are common to all methods:

Basic Liquid Penetrant Testing Steps

1. Surface preparation: This is the most critical step for excellent results. The surface must be very clean to allow penetrant to flow freely and penetrate into surface cracks.

2. Application of Penetrant: Liquid penetrant must be applied uniformly to the surface and allowed to dwell for a specified time period.

3. Removal of excess penetrant: Penetrant must be removed while taking care to not overwash the penetrant from cracks.

4.Development: Apply a thin layer of developer to draw penetrant to surface during a specified developer dwell time.

5. Inspection: Review surface indications for relevant and non-relevant indications.

Liquid Penetrant Testing Training (LPT)

Qualifying personnel to perform penetrant testing is a relatively efficient process. The training and on-the-job hours are published in ASNT and ISO standards. Qualified NDT personnel for penetrant testing may be certified as Level 1 or Level 2 technicians in accordance with employer standard operating procedures. In order to satisfy ASNT’s SNT-TC-1A: Personnel Qualification and Certification in Nondestructive Testing (2020) a Level 1 technician must complete at least 4 hours of formal training hours, at least 70 hours in the method or technique, and a total of 130 hours in total NDT hours to be eligible for certification. A Level 2 must complete at least 12 hours of training, at least 140 hours in the method or technique, and a total of 270 hours in total NDT hours to be eligible for certification.

TECHKNOWSERV Corporation offers hybrid NDT training that requires the candidate to complete the formal training on-line while performing practical training and testing in-person. The practical training and examination reinforces the principles taught via in on-line training in a hand-on environment. Liquid penetrant Level 1 and Level 2 practical training exercises prepare the student execute the five main testing steps common to all methods. This includes surface preparation, liquid penetrant application and dwell time, how to remove the excess penetrant properly without overcleaning, applying developer to pull out the penetrant in the defects, and the inspection and interpretation to report on relevant versus non-relevant flaws.

Figure 3 Developer pulling paint from flaws

Figure 4 Developer pulling paint from flaws

Figure 5 Penetrant testing station used during practical NDT training.

References:

ASTM E1417/E1417M-21 - Standard Practice for Liquid Penetrant Testing

ASTM E 165/E165M : 2018 Standard Practice for Liquid Penetrant Testing

ASM International / ASM Handbook Volume 17: Nondestructive Evaluation and quality control.

SNT-TC-1A: Personnel Qualification and Certification in Nondestructive Testing (2020)

ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel (ANSI/ASNT CP-189-2016)

ANSI/ASNT CP-105: ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (2020).

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

Comments