Destructive Testing of Fiberglass Storage Tanks: Ensuring Strength, Durability, and Compliance

- Thomas R. Hay, Ph.D., P.E

- Sep 17, 2025

- 5 min read

Updated: Nov 13, 2025

Fiberglass Storage Tanks and Destructive Testing: Ensuring Reliability and Safety

Fiberglass-reinforced plastic (FRP) is widely used for aboveground storage tanks (ASTs) and underground storage tanks (USTs). This material offers corrosion resistance, light weight, and a long service life. These tanks provide safe containment for fuels, chemicals, wastewater, and even potable water in industries where reliability is critical. However, the durability of a fiberglass tank depends on more than simply combining resin and glass. To perform as intended over decades, FRP tanks require verification of both their mechanical properties and their laminate composition. Without destructive testing, fiberglass tanks are at risk of cracking, deforming, or failing prematurely. Such problems can lead to costly repairs, environmental harm, and regulatory penalties.

The Importance of ASTM Standards

ASTM standards provide the framework for validating fiberglass tanks. Four methods, in particular, are essential for these tanks:

ASTM D3039-17: Measures tensile properties.

ASTM D790-17: Examines flexural behavior.

ASTM D695-23: Focuses on compressive strength.

ASTM D2584-18: Determines glass content through loss on ignition.

Together, these tests form the backbone of fiberglass tank quality assurance.

ASTM D3039-17: Tensile Testing of Fiberglass Tanks

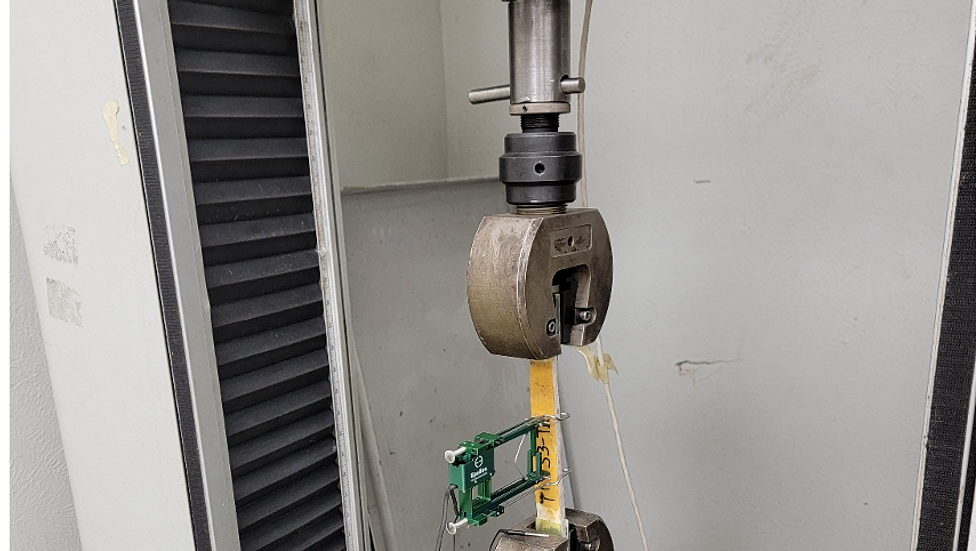

Tensile testing measures how a fiberglass laminate responds when it is pulled apart. Under ASTM D3039-17, flat coupons are cut from the tank wall or from companion panels cured alongside the tank. The samples are prepared with bonded tabs, mounted into a uniaxial testing machine, and pulled lengthwise until failure occurs. The resulting stress–strain curve provides three critical values: tensile strength, tensile modulus, and strain-to-failure.

For fiberglass storage tanks, tensile properties are particularly important. Underground tanks face external soil loads that place the walls under tension. Aboveground tanks must withstand the internal pressures of stored liquids. In both cases, thermal cycling—daily or seasonal expansion and contraction—adds to the stress. If tensile strength is inadequate, a tank may crack under service conditions. If tensile modulus is too low, the walls may stretch excessively, undermining structural integrity. By applying ASTM D3039 testing, manufacturers confirm that their tanks possess the strength and elasticity required for decades of safe operation.

ASTM D790-17: Flexural Testing of Fiberglass Tanks

Flexural testing focuses on how a laminate behaves when it is bent. ASTM D790-17 employs a three-point bending method. A rectangular coupon is placed across two supports and loaded at the midpoint until it deflects or fractures. From the load–deflection curve, engineers calculate flexural strength, flexural modulus, and strain at break.

Fiberglass storage tanks regularly experience bending forces. For underground tanks, the soil that surrounds them exerts constant external pressure, often magnified by groundwater. Aboveground tanks are subject to hydrostatic pressure from liquid contents as well as stresses that arise during installation and handling. Flexural stiffness helps prevent buckling, creeping, and distortion under these conditions. If the walls of a tank deflect excessively, localized stresses may cause cracking or leakage. ASTM D790 testing verifies that the tank laminate maintains enough rigidity to resist bending stresses over its service life.

ASTM D695-23: Compression Testing of Fiberglass Tanks

Compression testing examines how fiberglass composites behave under crushing loads. ASTM D695-23 requires a machined coupon—commonly a short cylinder or rectangular bar—to be loaded axially between two flat platens until it yields or fails. The stress–strain curve that results provides values for compressive strength, compressive modulus, and the laminate’s mode of failure.

This type of testing is particularly significant for underground tanks. Burial imposes tremendous compressive stresses from soil and groundwater. Tanks must withstand these loads without collapsing or delaminating. Aboveground tanks also depend on compressive strength to resist hoop stresses created by liquid weight and to withstand localized crushing from impacts or equipment. A tank that cannot manage compressive forces poses serious safety risks. ASTM D695 ensures that laminates are capable of carrying these loads without buckling, creep, or instability.

ASTM D2584-18: Glass Content Testing of Fiberglass Tanks

While mechanical tests are vital, the composition of a laminate also plays a decisive role in tank performance. ASTM D2584-18 determines the resin-to-glass ratio through a process known as loss on ignition. A small coupon is carefully weighed, placed in a furnace at approximately 550–600 °C, and held until all resin is burned away. The sample is then cooled, reweighed, and compared to its original mass. The difference represents the resin fraction, while the residue corresponds to the glass content.

The balance between resin and glass is crucial for fiberglass tanks. Too little glass reduces stiffness and strength, making the laminate prone to deformation and cracking. Conversely, too much glass leads to resin starvation, which reduces chemical resistance and creates pathways for wicking or voids. ASTM D2584 provides manufacturers with a standardized way to confirm that tanks meet design specifications for reinforcement. It also ensures compliance with industry standards such as UL 1316 for underground tanks and ASTM D3299/D4097 for aboveground tanks, both of which require appropriate glass content for long-term performance.

Compiling FRP Destructive Test Results

Each of these ASTM methods addresses a different aspect of fiberglass tank performance, but they are most powerful when used in combination. Tensile testing ensures that tanks do not crack or stretch excessively. Flexural testing verifies that tanks can resist bending under soil or hydrostatic loads. Compression testing confirms the laminate’s ability to withstand crushing and buckling. Finally, glass content testing provides the assurance that the material composition is balanced for both strength and corrosion resistance.

When taken together, these tests give manufacturers, regulators, and end-users a complete picture of a tank’s performance capability. They provide confidence that fiberglass tanks will perform reliably, comply with standards, and deliver decades of service under demanding environmental conditions.

Summary: Testing Builds Trust in Fiberglass Tanks

Fiberglass storage tanks are critical infrastructure in industries where safe, long-term liquid storage cannot be compromised. A single failure can be devastating—financially, environmentally, and reputationally. ASTM testing provides the assurance that FRP laminates are strong enough, stiff enough, and properly composed to meet their design requirements.

By following ASTM D3039, D790, D695, and D2584, manufacturers prove that their tanks meet rigorous performance standards. For engineers, regulators, and facility owners, these tests offer more than laboratory validation—they provide trust. Testing ensures that fiberglass tanks are not only built to code but built to last.

Additional Considerations for Fiberglass Tank Maintenance

Maintaining fiberglass tanks is essential for ensuring their longevity and performance. Regular inspections can help identify potential issues before they escalate. Here are some key points to consider:

Visual Inspections: Regularly check for signs of wear, cracks, or discoloration. Early detection can prevent significant failures.

Environmental Factors: Consider the tank's environment. Exposure to harsh chemicals or extreme temperatures can affect performance.

Professional Assessments: Engage professionals for comprehensive assessments. They can conduct advanced testing and provide recommendations for maintenance.

By prioritizing maintenance and adhering to ASTM standards, operators can significantly extend the life of their fiberglass storage tanks. This proactive approach not only enhances safety but also ensures compliance with industry regulations.

In conclusion, fiberglass storage tanks are a vital part of many industries. Their reliability hinges on rigorous testing and maintenance practices. By understanding and implementing ASTM standards, stakeholders can ensure the safe and effective use of these tanks for years to come.

I realized that while my skills were solid, the way I was presenting them wasn't holding up under scrutiny. I ended up looking for Resume Writing Services for Job Seekers to help me "stress-test" my professional history and make sure it met all the industry standards, much like the compliance checks you mentioned for these tanks. Once I had a solid foundation in place, my confidence grew, and I finally started seeing the results I wanted. It’s amazing how much a little specialized expertise can make a difference when you’re trying to build something that lasts!

I found this post on destructive testing of fiberglass storage tanks way more interesting than I expected, especially how engineers push materials to their limits to make sure they’re safe, strong, and up to code it’s a great reminder that testing failure can actually prove reliability. It made me think of late nights trying to Complete my online calculas class, where pushing through tough problems ultimately made the concepts much stronger in my mind.

I found your explanation of destructive testing for fiberglass storage tanks really informative, especially how it breaks down strength and safety standards in a way that’s easy to follow. It took me back to a semester when I was juggling technical projects and pressure of completing so, I had to take my online class for me during that crunch just to free up time to dive deeper into topics.

Reading your deep dive into destructive testing of fiberglass storage tanks really pulled me into the nuts and bolts of why strength and compliance matter so much in real‑world engineering, and it reminded me of the first time I watched a pressure test in a materials lab and couldn’t believe how predictable failure can be when you understand the science. That same mix of nerves and preparation makes me laugh thinking about my online Accounting exam jitters during finals week, when I wished I could bring that same calm precision to my spreadsheets.

While reading this piece on destructive testing, I was reminded of sitting late nights reviewing a complex academic draft every stress test here felt like a reviewer’s comment, pushing materials to their limits so hidden weaknesses surface early. That same quiet discipline defines a research paper editing service, where careful scrutiny, patience, and small corrections quietly strengthen the final work without ever calling attention to themselves.